If you’re operating a small business, you’re always thinking about how to make your product or service as good as it can be. And you’re putting the best of those ideas into action.

But are those changes having a tangible impact on customer satisfaction? Are there other areas where your resources would be better spent?

Effective management isn’t just about profit margins. It’s also about prioritizing the customer, who you depend on to drive success.

This is also referred to as having a customer focus, and it prioritizes the needs and wants of the buyer above any other factor. It’s central to all approaches to Total Quality Management (or TQM for short). Let’s look at how to take this and other key principals, and effectively apply them within the context of your unique business.

What Is Total Quality Management?

Always put the customer first.

The U.S. market faced competition from Japan in the late 1970s and early 1980s. Japan was able to produce high-quality automotive and electronic products at lower prices.

As a result, businesses in the U.S. looked more closely at the quality of Japanese products. Their goal was to find ways to recapture their lost share of the market through improved products. What could they learn from their competitors?

The solution was TQM. Everything you need to know is right in the name:

- Total refers to the involvement of all team members, from product development to customer service. Everyone in the business is focused on the same goal, and each department is held responsible for what it contributes to the overall Customer Experience (CX).

- Quality is the ultimate goal of TQM. More specifically, it’s about increasing product or service quality, and as a result offering more value to customers.

- Management encompasses everyone who oversees the process of TQM implementation, identifying and resolving points of friction in order to improve efficiency.

Since the framework, methods, and practices became popular in the mid 1980s, your business might already be employing TQM practices without realizing it. They’re still just as relevant today. As a customer-focused management style, TQM drives stable, long-term success.

5 Approaches To Total Quality Management for Your Small Business To Consider

TQM is a fairly broad concept. The ways it’s applied take various names and forms. But all are centered on the idea of developing your product to ensure customer loyalty and satisfaction.

The following approaches to total quality management are all worth investigating. Whether you adopt them wholesale, or adapt the parts most relevant to your business model, they can transform everything from how you handle customer support interactions to how your products are designed.

1. Lean Management

Lean Management, also known as just “Lean”, focuses on waste reduction. The goal is to target and eliminate unnecessary processes, thereby increasing efficiency.

Everything you do should add value for the customer. Resource sinks and time-consuming tasks that don’t create value can be cut out. When done right, this improves your profitability, and it enhances quality by ensuring that everything you do improves customer satisfaction.

The Five Principles of Lean Management

Applying this approach to total quality management requires prioritizing five principles:

- Identify value. Identify the problem customers need solved, and develop your product or service into the ideal solution. Any process that doesn’t add value to the final product should be removed.

- Carry out value stream mapping. Map out key workflows, so you can see each step and how they all connect. This is vital for finding unnecessary elements, redundancies, and so on.

- Create a continuous workflow. Prevent any cross-functional teamwork bottlenecks. Breaking down the entirety of a work process into smaller parts makes it easier to remove roadblocks.

- Establish a pull system. Ensure that the workflow remains stable. This is a lean-specific technique that decreases the waste of production processes. For example, new work should only be started if there is demand for it, reducing unnecessary overhead.

- Facilitate continuous improvement. Use various techniques to identify what your organization has done, what it needs to do, and how all team members can make work processes easier.

2. Six Sigma

Six Sigma is a variation on the Lean philosophy. It was developed by Motorola in the 1980s, although Toyota was the company that made it most famous. Many books have been written about the methodology behind Six Sigma, its variations, and Lean in general.

This particular strategy is very data-driven, to align with manufacturing principles while still keeping the customer in mind. To an extent, it prioritizes efficiency in the now versus long-term thinking, which is where it slightly differs from other approaches to total quality management.

Six Sigma is aimed at eliminating any defects from a process. In the case of Toyota, by using Six Sigma principles it was able to pinpoint friction in the engine production process. This led to a decrease in defective units, and helped to identify bottlenecks throughout the supply chain.

Six Sigma’s Five-Step Approach: DMAIC

While the details are complex, the basic steps of Six Sigma can be summarized as follows:

- Define. A team, typically led by someone certified in Six Sigma, identifies a process to focus on and defines the problem to be solved.

- Measure. The team measures the performance of the process, and creates a benchmark goal. They then create a list of things that might be hindering performance.

- Analyze. The team analyzes the process by looking at each input or reason for failure/friction, and explores it through testing to find the actual root cause(s).

- Improve. The team implements changes to solve the problem and meet the desired benchmark.

- Control. Finally, the team decides on ‘control parameters’ to monitor, chosen to ensure that the problem doesn’t arise again.

The “KAIZEN” philosophy is an adaptation of the Six Sigma framework, and is all about continuous improvement. Initially developed to reduce waste in manufacturing, Kaizen’s guiding star is that everything can always be done better or improved on.

All problems should actually be seen as blessings, and as opportunities to develop your product or service. Kaizen has its own set of key principles, and is an equally interesting methodology.

3. ISO 9000

ISO 9000 is a set of standards for Quality Management Systems (QMS). These standards act as functional guidelines for the implementation of quality management.

“ISO” refers to the “International Organization for Standardization” (ISO), which develops international standards for numerous industries. It formalized the general principles of TQM into a set process that companies can become “certified” in.

Even without pursuing that official certification, though, ISO 9000 provides a unique starting point for businesses looking to maximize quality. It offers definitive guidelines by which to evaluate internal processes for efficiency.

ISO 9000s Quality Management Principals

The ISO 9000 family of standards is based on seven quality management principles:

- Customer focus. The insistence on customer needs and requirements is a recurring trend throughout all approaches to total quality management.

- Leadership. Without the support of management, no ISO (or TQM) system can function effectively. Management needs to be involved in every decision and step.

- Engagement. Employees are a key resource for identifying and resolving problems through communication. Team members can contribute to improving all processes, from development to customer service.

- Process approach. It’s essential to analyze and scrutinize each individual variable in the development of a product.

- Improvement. The ISO 9000 series forms a more structural approach to improvement, in which all employees are involved. A “culture of quality” is fostered through measurement of performance across the entire organization.

- Evidence-based decision making. Evidence-based decisions should be made based on the collection of objective data, qualitative survey results, etc.

- Relationship management. Businesses that closely monitor and respectfully tend to internal and external relationships nurture more productive and positive involvement, creating a feedback loop of engagement.

4. Quality Function Deployment

Quality Function Deployment (QFD) is a methodology for translating customer needs and expectations into specific products or service features. The development of our own helpdesk software, Groove, is a great example of QFD in action.

In the initial stages of Groove’s development, we didn’t collect much customer feedback. We weren’t building a product based on the needs of our future customers. We were building it based on our assumptions of what they wanted.

Success came more readily when we put the voice of the customer (VOC) first. This is a key concept of QFD, and encompasses both stated and unstated customer needs.

The VOC can captured through customer satisfaction surveys, interviews, social media conversations, focus groups, observation, and even field reports. Any and all direct feedback is valuable.

The goal is to use that feedback to prioritize the right elements in the production and development stages. Feedback loops are then used to refine product development.

Four Stages of Quality Function Deployment

The comprehensive process of QFD is typically divided into four stages:

- Product planning. Listen to the customer, collect feedback, and capture the VOC. Interpret their requirements and consider those as design or service features.

- Design deployment. Identify the design characteristics or product features that directly correlate to customer concerns.

- Process planning. Determine your manufacturing processes or development processes. Identify the specific operations – the steps for assembly or production that correlate to the desired design characteristics.

- Production planning. Design, build, and implement the manufacturing or production process laid out in the third stage. Develop control requirements (what should be monitored during production), and establish maintenance requirements.

5. PDCA

PDCA stands for Plan-Do-Check-Act, or sometimes Plan-Do-Check-Adjust. It’s a four-step process that sustains continuous improvement within an organization or business:

- Plan: Establish objectives and processes.

- Do: Implement the plan.

- Check: Assess and evaluate the collected and measured results.

- Act: Apply appropriate changes based on the results.

PDCA is used to control the improvement of a process or product. It’s closely related to both the Six Sigma methodology and the overall Lean approach.

The goal of the PDCA cycle is to identify potential problems and present multiple solutions, adjusting accordingly. It’s one part of an entire systematic process for improvement. Because this is a cycle, it doesn’t end after the “act” step, but starts all over again.

Trying out PDCA within your own business starts with three questions:

- What are you trying to accomplish?

- How will you identify that a change is an improvement?

- What changes can you make that will result in improvement?

You should be clear when answering these questions, formulating specific goals with set timelines. PDCA calls for corrective actions and actionable steps to incite change.

3 Tips for Applying Total Quality Management To Your Small Business

Implementing these approaches to total quality management can seem a little daunting. We’ve only scratched the surface here, but it’s already clear how much work and complexity is involved.

But you don’t have to become an expert in one of these methodologies to achieve success. There are plenty of ways to proactively apply the core ideas of TQM without an extensive course or fancy certification. Here are a few ways to get started.

Tip #1: Identify and Understand Customers’ Needs

The core of any TQM strategy is a central focus on the customer. This is the number-one lesson to take away from all these approaches to total quality management.

Account for customer needs when making any internal decision, whether that’s a process change, a new service, or a feature update. Consider how it will impact your customers. Is a new software integration likely to result in measurable customer success, or wind up unused and unappreciated? And do you know the answer, or are you just guessing?

What steps can you take to better understand customers’ needs?

To start, customer journey tracking can help you better understand buyers’ experiences. You need to understand how they move through the various stages of the consideration/purchasing process and become a long-term user of your product/service.

Creating a map of the customer journey identifies touchpoints may involve friction. Tracking the journey tells you whether that friction is present and what’s causing it. Addressing those pain points can improve retention, increase conversion, and cut churn rates.

Let’s say that your checkout page is unresponsive or confusing. You’ll probably notice a higher bounce rate when assessing metrics.

You might test out a single-form checkout page instead, to see if it reduces frustration and improves conversions. But whatever solution you opt for, the key is to stay focused on the customer’s perspective.

You’re not trying to increase sales. You’re trying to provide a checkout process that’s easy and clear for your customers. The end result is still (ideally) improved revenue. But the difference in mindset helps you avoid wasted time and make only what changes are needed.

Tip #2: Place Emphasis on Customer Satisfaction

The quality you offer to customers isn’t solely defined by how good your product or service is. It’s a result of the entire customer experience you offer, from the first interaction to the tenth subscription renewal.

Customer service plays a key role in helping you exceed expectations. Exceptional service builds loyalty and keeps satisfaction high. In other words, TQM can be implemented through high-quality communication and support.

That level of quality requires skilled, dedicated team members. It also requires supporting them with the right tools. Our helpdesk Groove enables your team to deliver world-class service through automation features, integrations, ticket assignment, and self-service.

Let’s single out a key feature and take a closer look. One way to apply the principles of TQM to customer support is by offering a self-service knowledge base:

Time is valuable to customers. But if your team has a lot of tickets to respond to, you might need some way to help buyers help themselves.

Customers just need answers to their questions. If they can get those answers in an easily-accessible knowledge base article, they save time by avoiding the need to reach out to support.

By focusing on the most efficient way to provide the value buyers are looking for, you eliminate heaps of repetitive conversations and save time for your team too. With Groove, you can build your own self-service resource to be as comprehensive as customers want.

Tip #3: Collect Actionable Consumer-Focused Feedback

Any direct feedback you can obtain from your customers is gold. It enriches your development process, helps you create higher customer satisfaction, and avoids time wasted on unnecessary changes or testing.

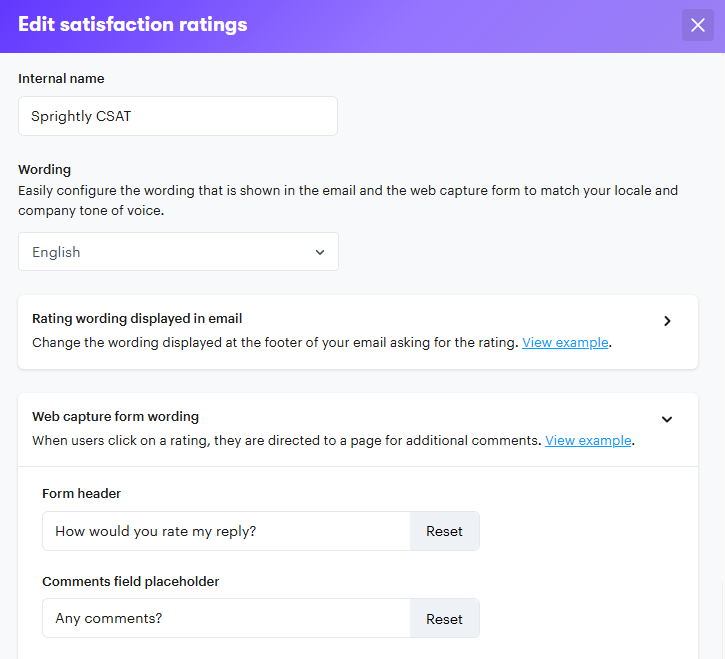

Customer surveys are a great place to start. They allow for both qualitative and quantitative data collection. In particular, customer satisfaction (CSAT) surveys provide baseline information about how well you’re meeting users’ needs.

You can easily customize and send out CSAT surveys via Groove. They can be embedded right into your emails, making it simple for customers to share their feedback via a numbered rating and a free-form response option.

All approaches to total quality management rely on giving the customer what they want. Survey data, focus groups, and even A/B testing are essential for seeing your business through your real customers’ eyes (not the eyes of an imagined, ideal buyer).

Understanding and Applying The Cost of Quality

The phrase “cost of quality” refers to the fact that doing things right the first time costs you less in the long run. You avoid the need to redo or undo changes, and you lose fewer customers due to misaligned expectations. We’ve definitely learned that the hard way at Groove.

Aside from the focus on customers, the key element of TQM is the “total” aspect. You need all of your employees working together towards the same philosophy. Ultimately, that matters more than the specific flavor of TQM you opt to try.

Groove ensures that everyone involved in support can collaborate effortlessly. It’s an all-in-one helpdesk solution that facilitates a TQM approach to customer satisfaction. Sign up for a free trial and see how!